A few years ago, I worked on a project where I was asked to document a delay claim. I was working as a Primavera P6 planning for an electrical supplier who had subcontracted out the construction of a number of electrical buildings to a fabrication yard. The main design engineer made a number of fundamental design changes in the first year of the project. Communication and contract issues between my employer and the fabrication yard resulted in a delay of over a year from the original contract date to the final delivery.

To make matters worse, there were no schedule updates over the period of the delay. The only firm Primavera P6 schedules that I had were the original contract schedules and the as-built schedule that I updated when I was contacted for the project.

There were a number of colourful characters working on the project and on more than one occasion security had to be called to remove one of the project team from a particularly heated contract discussion.

This was the first major delay claim I had been involved in. I would like to outline what we did in the circumstances and the issues that I dealt with. This is not the textbook example of how to manage a delay claim with Primavera P6 but hopefully it will highlight a few interesting areas of discussion here on Plan Academy.

The Challenge

My job started in less than ideal circumstances. The project team had changed over the life of the project and only one person had been present since the start. The subcontractor who was building the electrical buildings at the heart of the project was not communicating with the client due to payment disputes. The schedule had not been updated regularly enough to demonstrate a clear picture of how changes in the engineering design had affected the construction process of the electrical buildings.

I had the schedule that existed at the start of the project. I used this as the project baseline and I used the as-built schedule as the current project. However, I was under pressure from the project manager to create a hypothetical baseline that did not correspond with the original baseline schedule. This was an after the fact addition that did not make use of project documentation that was officially issued at that time in the project. This caused about a month of confusion and eventually we got rid of it as the extra detail did not help our case.

The construction process had been started and stopped for about 2 months due to late change notices. I simply spanned these periods of time with an activity that represented the delay. The delay periods were then given a daily delay cost and presented to the client as part of the claim along with the supporting documentation.

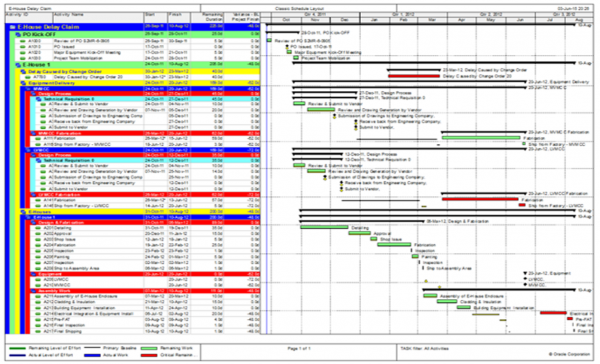

An Example of the Schedule

I have attached a screen shot of the schedule that I prepared as part of the claim. The original project schedule is saved as a baseline and the current schedule demonstrates the impact of the change order on the electrical building fabrication. The original baseline is compared to the final delivery date and the difference of 48 days is attributed to Change Order 20. The evidence that supported Change Order 20 was presented in a separate detailed file. The schedule illustrated the impact of the project delay on the final delivery of the electrical buildings.

What does the literature say?

According to “CPM in Construction Management” by O’Brian and Plotnick, a CPM schedule can affect a delay claim in two key ways:

- It establishes a realistic schedule through CPM planning, which can furnish a legal basis for the enforcement of damages.

- Perhaps even more importantly, it can be used to evaluate actual claims through the reconstruction of a projects history or the use of an existing CPM plan to indicate the effects of changes on the original schedule.

A key success factor at presenting a convincing delay claim is the quality and accuracy of the project record keeping. In our case, a number of errors in record keeping were detrimental in the reconstruction of the project’s history.

Saleh Mubarak’s book “Construction Project Scheduling and Control” identifies a number of frequent scheduling mistakes in relation to delay claims. The following mistakes were made on my project.

Erasing the Baseline Footprint.

The previous scheduler had updated the baseline schedule as the worked progressed and did not save regular baselines to create a project record. This meant that I did not have an accurate picture of how key project events delayed the completion of the electrical buildings. Luckily, we had a baseline that was provided at the start of the project that I could recreate to compare the original baseline with the as-built schedule. The lack of detail in between the project start of finish points was detrimental to the delay claim.

Unrealistic Baseline Schedules.

The project team were under pressure to get the contract signed and the baseline schedule was extremely aggressive. When the design delays were taken into account, the schedule was unrealistic and set the project team up for failure from the start.

Skipping Periodic Updates

The previous project scheduler did not save any baselines during schedule updates and he did not move the data date to allow the CPM calculations to work correctly. This meant that it was hard to paint a credible picture of how the project slipped off track one update at a time.

Lack of Proper Documentation

The project lacked a regular record of the important project events. The meeting minutes recorded the details of all the project negotiations and the documentation control system had a huge amount of documents had been transmitted between the parties. What was lacking was a schedule-specific account of the project progress as it happened. This record would have been very useful in referencing both the meeting minutes and document control system with supporting evidence. P6 has an issue tracking and note taking capacity that is very useful for adding details of project events that are difficult to represent on a Gantt chart.

Conclusion

One of the roles of a regularly updated project schedule is to provide the project team with an accurate history of the work flow in case of a dispute at the end of a project. I found that the experience of preparing a delay claim with very poor project records really educated me about the need for record keeping over the life of the project.

The delay claim concluded with a negotiation between the electrical supplier and client. As they had an ongoing relationship, the issues were negotiated by a steering committee made up of senior management. The claim schedule played a key role in illustrating the effects of the design delays on the project. The delay claim was settled, but I think the electrical supplier would have done significantly better had they kept better records and updated their schedule properly over the life of the project.

I was wondering if any of the readers here on Plan Academy have any experiences documenting delay claims or project disputes. What techniques did you use and how effective did you feel a CPM schedule was at illustrating the causes of the delay or interruption?